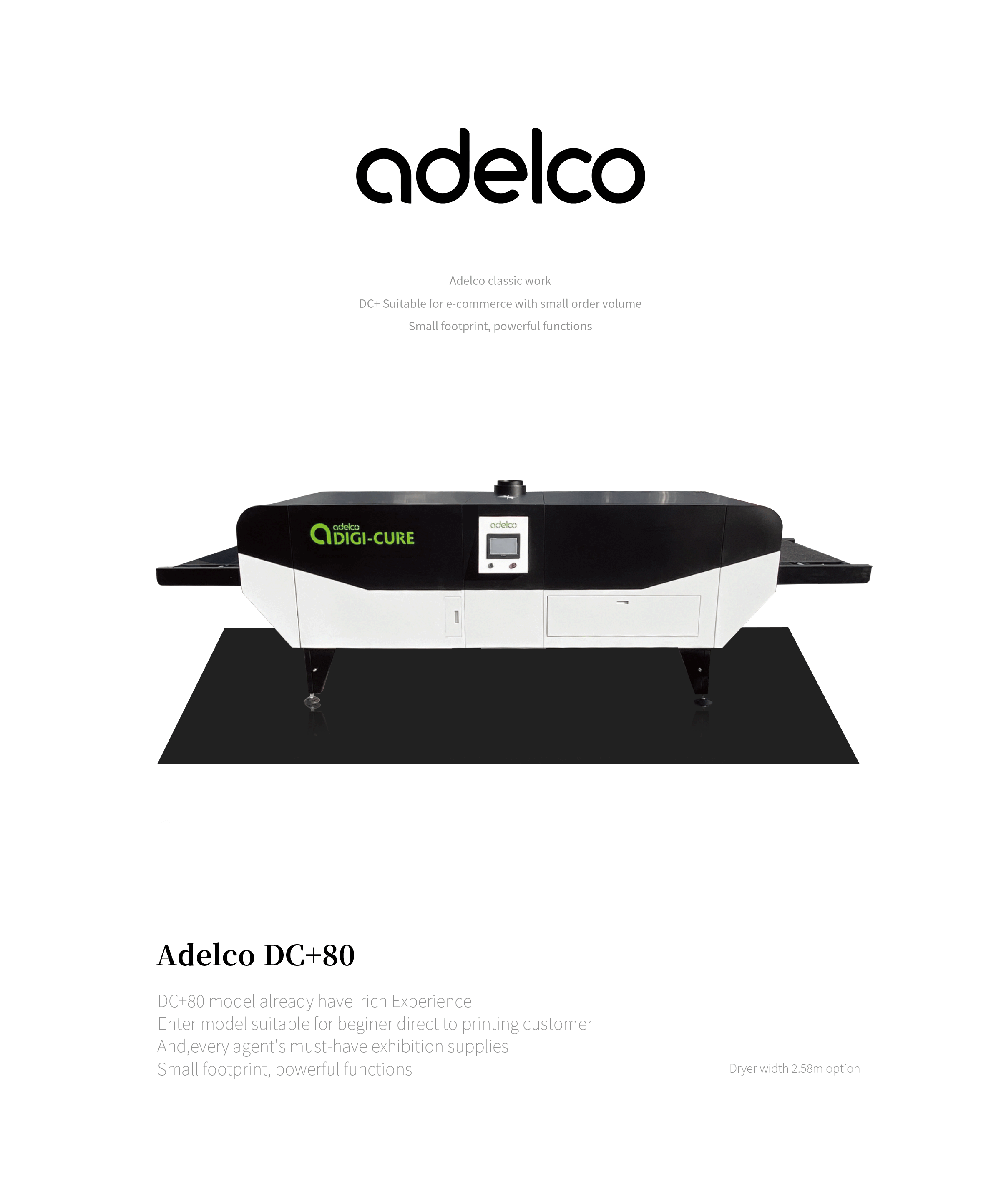

DC+80

Key words:

Classification:

DC+80

Adelco's Tunnel Drying Solutions: A Testament to 30 Years of Innovation and Efficiency

For over three decades, Adelco has been at the forefront of tunnel drying technology, setting industry standards with its unwavering commitment to innovation and efficiency. Specializing in tunnel drying, Adelco has mastered the art of drying processes, ensuring optimal results while minimizing cost losses through its advanced hot air circulation system.

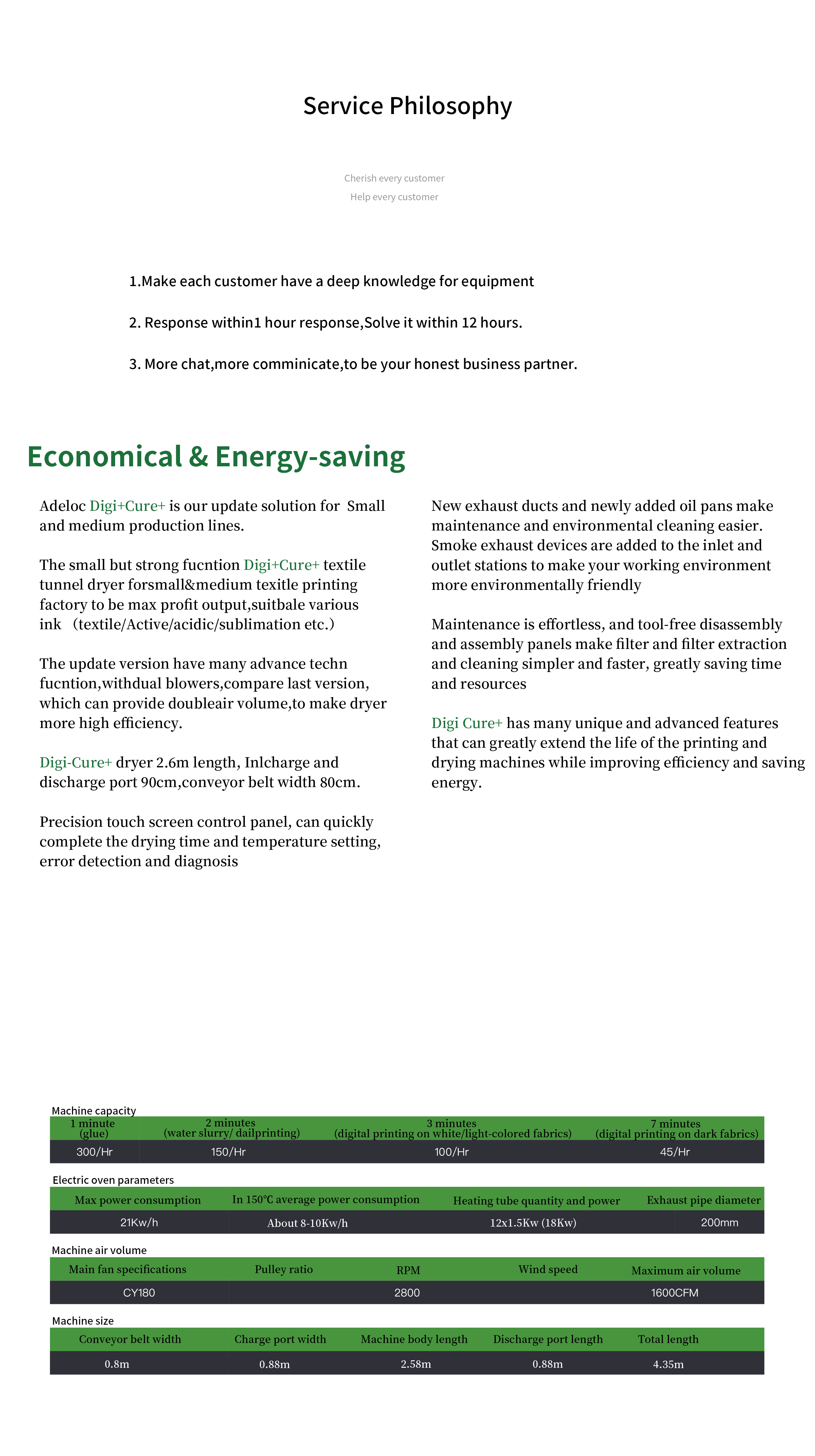

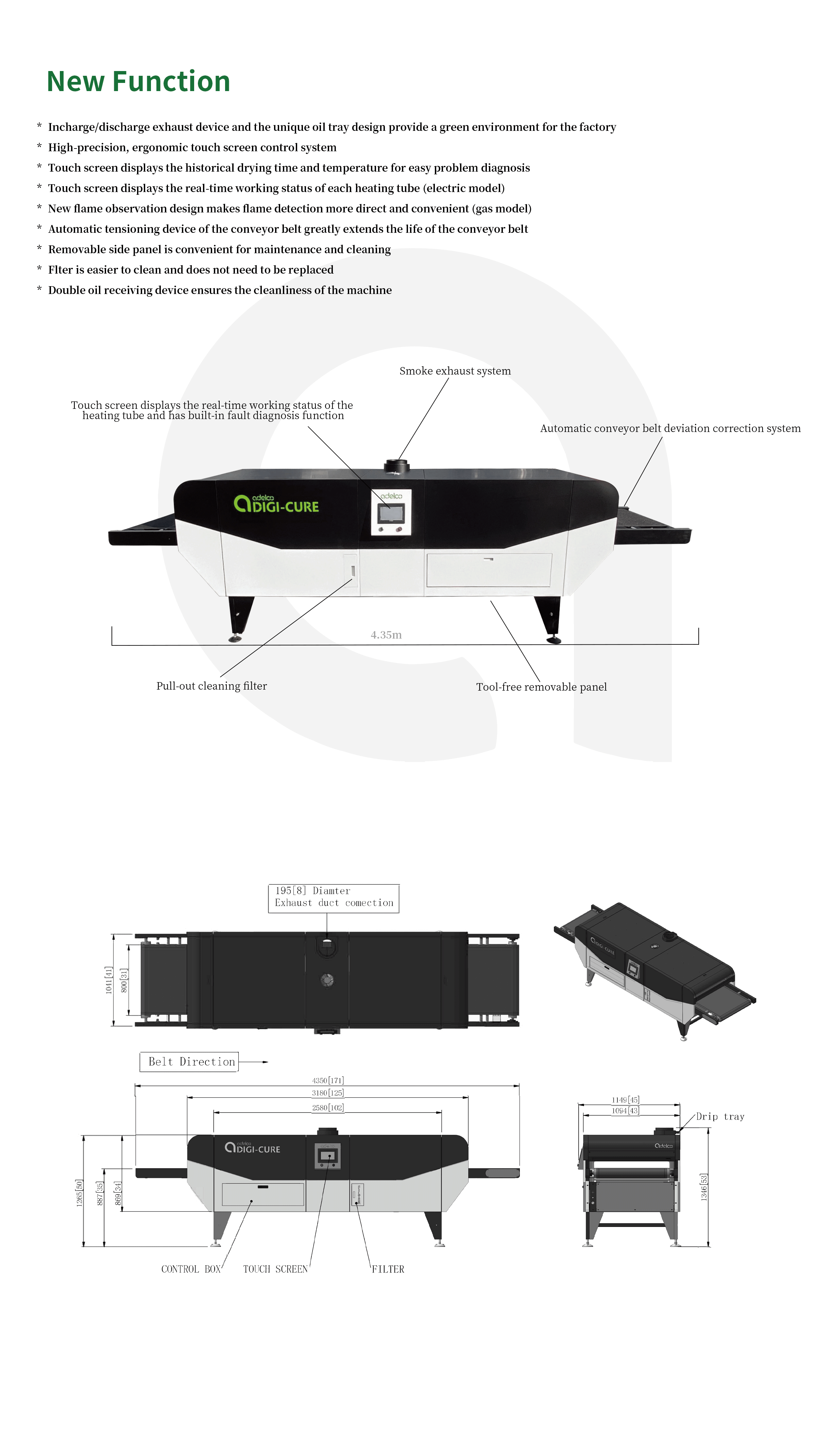

At the heart of Adelco's success lies its specialized focus on tunnel drying, a technique that utilizes a continuous conveyor system to transport materials through a heated chamber. This method is particularly advantageous for large-scale operations where consistent and efficient drying is paramount. Over the years, Adelco has refined this technique, incorporating state-of-the-art features that enhance performance and reliability. The company's dedication to tunnel drying is evident in its ability to cater to diverse applications, from food processing and pharmaceuticals to woodworking and textile manufacturing.

One of the standout features of Adelco's tunnel drying systems is its adoption of an advanced hot air circulation system. Unlike conventional drying methods that may struggle with uneven heat distribution, Adelco's system ensures uniform drying by circulating hot air throughout the chamber. This meticulous control over airflow not only improves drying efficiency but also preserves the quality of the product being dried. By maintaining consistent temperatures, Adelco's systems prevent overdrying or underdrying, which are common issues in less sophisticated setups.

The insulation effect achieved through Adelco's tunnel dryers is another testament to their engineering prowess. Effective insulation minimizes heat loss, allowing the system to operate more efficiently and reducing energy consumption. This is particularly important in industries where energy costs constitute a significant portion of operational expenses. By investing in high-quality insulation materials and designs, Adelco ensures that its tunnel dryers maintain optimal temperatures without wasting energy, thereby contributing to cost savings for its clients.

Reducing cost losses is a primary goal for any business, and Adelco understands this all too well. Its tunnel drying solutions are designed with cost-efficiency in mind, aiming to provide the best return on investment for its customers. By optimizing drying times and improving energy efficiency, Adelco helps businesses lower their operational costs without compromising on product quality. Additionally, the reduced risk of product spoilage due to improper drying further safeguards against financial losses, making Adelco's solutions even more valuable.

Adelco's commitment to innovation extends beyond just the technical aspects of tunnel drying. The company continuously seeks feedback from its clients to improve its products and services. This customer-centric approach ensures that Adelco remains attuned to the evolving needs of the market and can offer solutions that are not only technologically advanced but also practical and user-friendly.

In conclusion, Adelco's three-decade-long specialization in tunnel drying has solidified its position as a leader in the field. Through the adoption of an advanced hot air circulation system, exceptional insulation effects, and a relentless pursuit of cost reduction, Adelco has set new benchmarks for efficiency and reliability in tunnel drying. As industries continue to evolve, Adelco's innovative spirit and dedication to excellence will undoubtedly drive further advancements, ensuring that it remains at the cutting edge of tunnel drying technology for years to come.

Related Products

Get free product quotes